Business inventory control systems are indispensable tools for businesses of all sizes, enabling them to effectively manage their inventory, optimize stock levels, and streamline their supply chain. These systems provide real-time visibility into inventory levels, allowing businesses to make informed decisions, reduce waste, and improve customer satisfaction.

From defining the fundamentals of inventory management to exploring emerging trends in the field, this comprehensive guide delves into the intricacies of business inventory control systems, empowering businesses to gain a competitive edge in today’s dynamic market.

Inventory Management Fundamentals

Inventory management plays a pivotal role in ensuring the smooth functioning of businesses. It involves the tracking, managing, and controlling of raw materials, work-in-progress, and finished goods within a supply chain.

An inventory control system is a set of policies and procedures that businesses use to manage their inventory. These systems help businesses to optimize their inventory levels, reduce costs, and improve customer service.

Types of Inventory Control Systems

There are different types of inventory control systems, each with its own advantages and disadvantages. The most common types of inventory control systems include:

- Periodic inventory system:In a periodic inventory system, inventory is counted and recorded at regular intervals, such as monthly or quarterly.

- Perpetual inventory system:In a perpetual inventory system, inventory is continuously tracked and updated as transactions occur.

- Just-in-time (JIT) inventory system:In a JIT inventory system, inventory is ordered and received only as needed, minimizing the amount of inventory on hand.

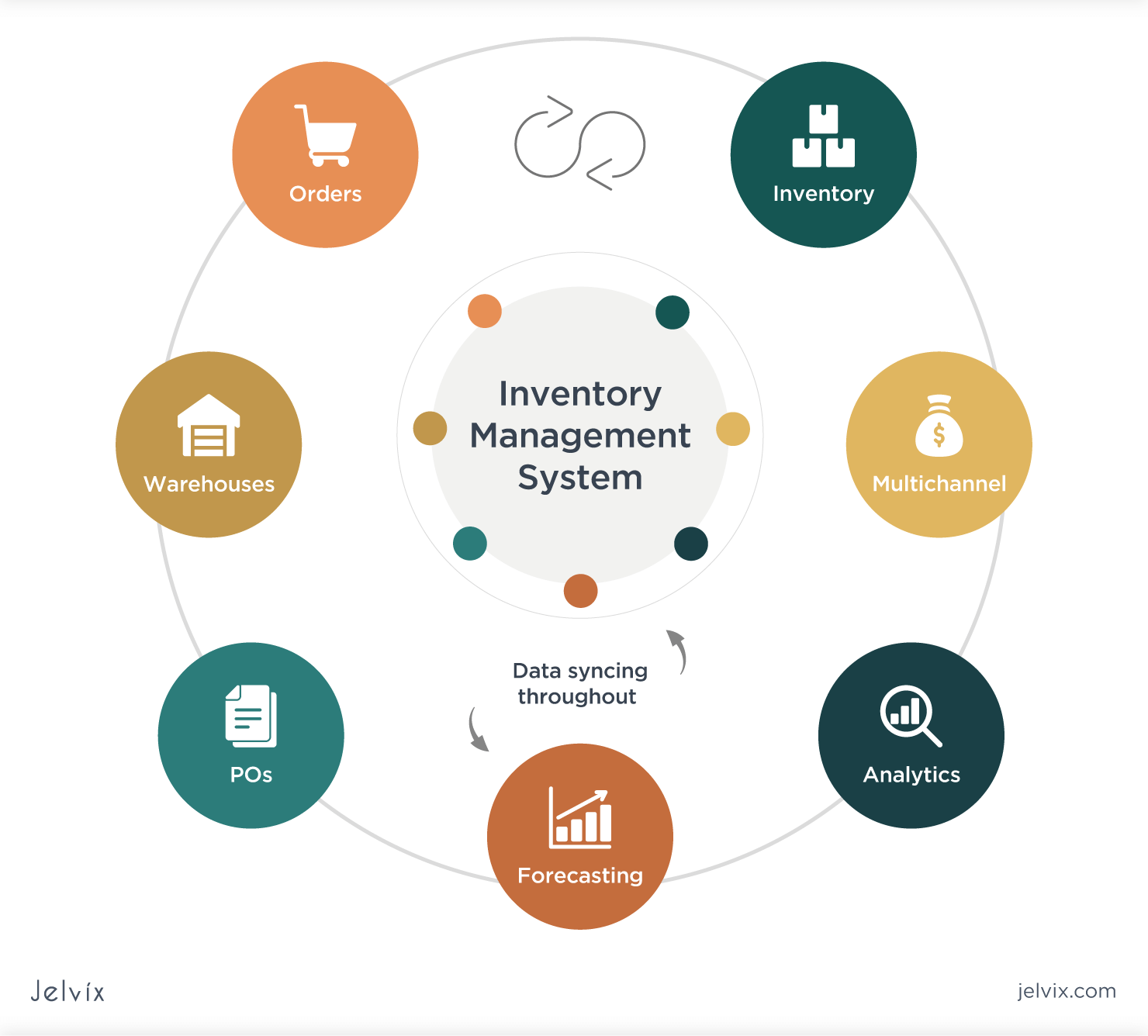

Key Components of Inventory Control Systems: Business Inventory Control Systems

Inventory control systems are designed to provide businesses with visibility and control over their inventory. They consist of several key components that work together to ensure that inventory levels are optimized, costs are minimized, and customer demand is met.

The key components of an inventory control system include:

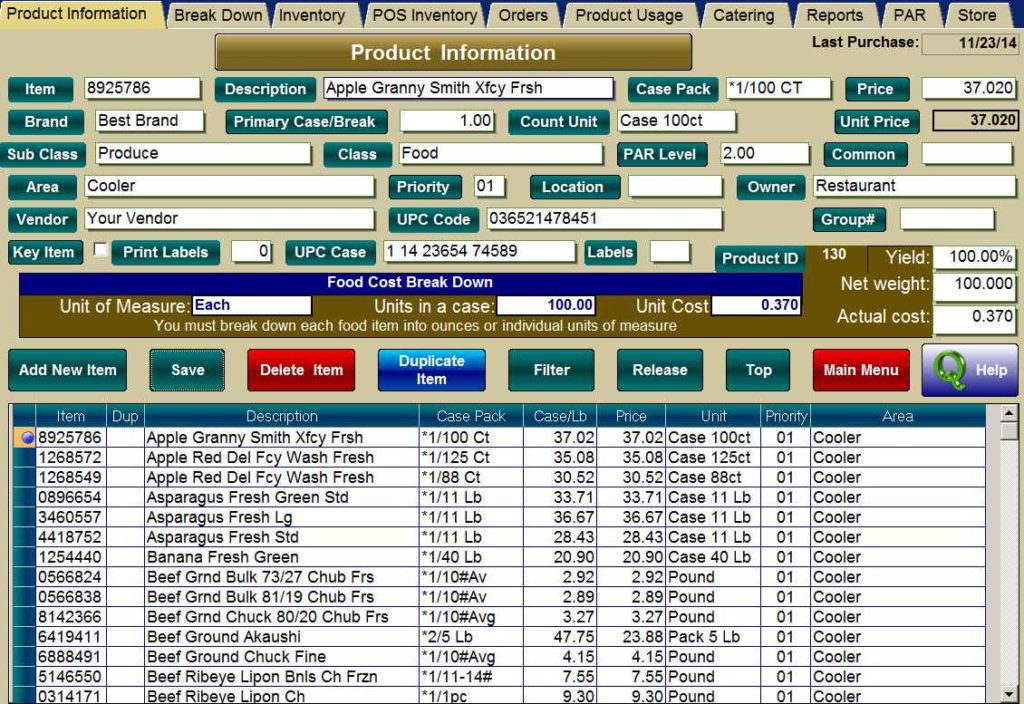

- Inventory management software:This software is used to track inventory levels, manage orders, and generate reports. It can help businesses to automate many of the tasks associated with inventory management, such as reordering and tracking stock levels.

- Barcoding and RFID technology:These technologies are used to identify and track individual items of inventory. Barcodes are typically printed on product packaging, while RFID tags are small electronic devices that can be attached to items. These technologies allow businesses to quickly and accurately track inventory levels and movements.

- Inventory control policies:These policies define the rules and procedures for managing inventory. They typically include guidelines for setting inventory levels, reordering inventory, and handling damaged or obsolete inventory.

- Inventory forecasting:This process involves predicting future demand for inventory. Businesses use inventory forecasting to determine how much inventory they need to keep on hand to meet customer demand without overstocking or understocking.

- Inventory optimization:This process involves finding the optimal inventory levels for a business. Businesses use inventory optimization to minimize inventory costs while ensuring that they have enough inventory to meet customer demand.

These components work together to provide businesses with a comprehensive inventory control system. By using these components, businesses can improve their inventory management practices, reduce costs, and improve customer service.

Inventory Control Techniques

Inventory control techniques are strategies and methods used by businesses to optimize inventory levels, reduce costs, and improve efficiency. These techniques help businesses maintain the right amount of inventory to meet customer demand while minimizing waste and spoilage.

Just-in-Time (JIT) Inventory

JIT is an inventory management technique that aims to minimize inventory levels by receiving and using materials only when they are needed for production. This technique reduces storage costs, frees up capital, and improves inventory turnover.

ABC Analysis

ABC analysis is a technique used to classify inventory items based on their value and usage. Items are categorized into three groups: A (high-value, low-usage), B (medium-value, medium-usage), and C (low-value, high-usage). This analysis helps businesses prioritize inventory management efforts and focus on the most critical items.

Economic Order Quantity (EOQ)

EOQ is a formula used to determine the optimal quantity of inventory to order at a time. It considers factors such as demand, holding costs, and ordering costs to minimize total inventory costs.

Safety Stock, Business inventory control systems

Safety stock is an additional amount of inventory held to buffer against unexpected fluctuations in demand or supply. This technique helps businesses avoid stockouts and maintain customer satisfaction.

Kanban System

Kanban is a visual inventory control system that uses cards to track inventory levels. When inventory reaches a predetermined level, a kanban card is generated, triggering the replenishment of inventory.

Ending Remarks

In conclusion, business inventory control systems are essential for businesses seeking to optimize their inventory management practices. By implementing these systems, businesses can gain greater control over their stock levels, reduce costs, improve customer service, and ultimately drive business growth.

As technology continues to advance, inventory control systems will only become more sophisticated, providing businesses with even greater opportunities to streamline their operations and achieve success.